News

Ultrasonic Thickness Gauges: Benefits of Sonic Readings

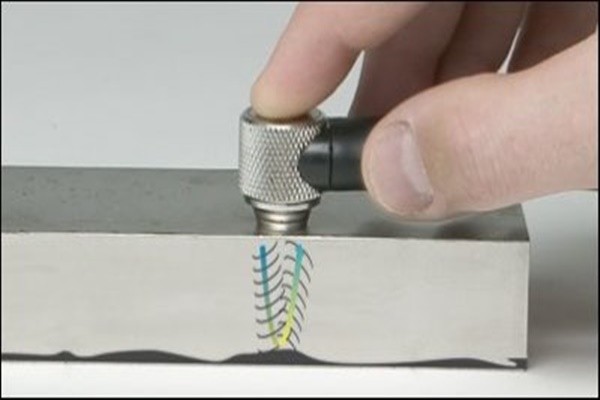

As we briefed in our January news article about pen type thickness gauge A1207, we would like to describe about the benefits of using ultrasonic method in thickness gauges. In dimensional measurement Ultrasonic thickness gauges use sound wave propagation method to get accurate read of the remaining wall thickness. Thickness is measured for metal and plastic pipes, boilers, vessels etc. To get the idea about how this method works, let us dig deep into the subject. Thickness is measured as depth of sea is measured by ships using SONAR technique. Sound pulses are sent to travel from the transducer to the opposite side of the object, it comes back and received by the transducer. Thickness gauge converts the time taken by the signal to thickness of the object and display it on the screen. Now since it is clear how it is used, important issue is why it is used. Ultrasonic Technology is a reliable method of inspection with a wide variety of usefulness. It helps in regular inspection of various metal and plastic pipes, boilers and vessels. Regular inspection will keep the company informed about any sign of repairs in their products. It also just measures from only one side of the object therefore no cutting of sections required in the object. Testing is quick, accurate and reliable. It doesn’t require a necessary laboratory conditions. Many of ultrasonic thickness gauges are very handy just like our A1207 (a pen type gauge). To learn more about their uses and benefits, contact us today on 0522-4027541 or info@russelltech-india.com