News

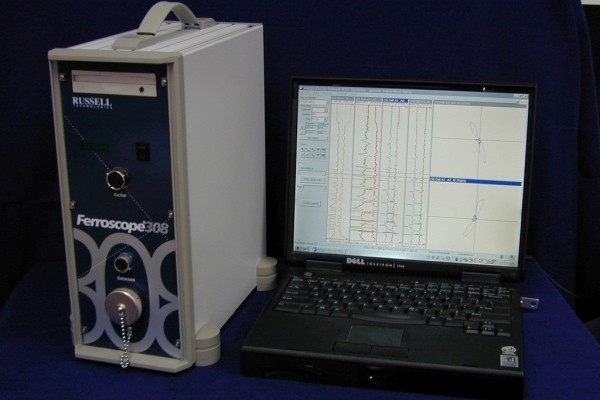

Effective Methods for Inspecting Carbon Steel Tubing : FERROSCOPE 308

Carbon steel tubing is frequently found in boilers and heat exchangers. They are commonplace and frequently used in the Power generation stations, Petrochemical plants, Petroleum refineries and Natural gas processing plants. RTI recognizes that the inspection and monitoring of carbon steel tubing is extremely important. It can be very inconvenient and expensive when exchangers and boilers fail, causing plant shutdowns and loss of production.Our company uses the most advanced methods when inspecting carbon steel tubing in boilers and heat exchangers to cut down the time it takes to analyze the pipes. A large variety of NDT methods are available for the condition assessment of heat exchanger and boiler components.There are four main technologies used for the inspection of steel tubing which use internal probes travelling through the length of the tube :'SATURATION EDDY CURRENT', 'REMOTE FIELD TECHNOLOGIES', 'INTERNAL ROTARY INSPECTION SYSTEM (IRIS)'&'MAGNETIC FLUX LEAKAGE (MFL) '. If your company uses heat exchangers or boilers with carbon steel tubing, Russell Technologies India has the expertise and technology to inspect these devices. Contact us at (0522) 4027541 or by e-mail at info@russelltech-india.com to hire us for your next inspection.